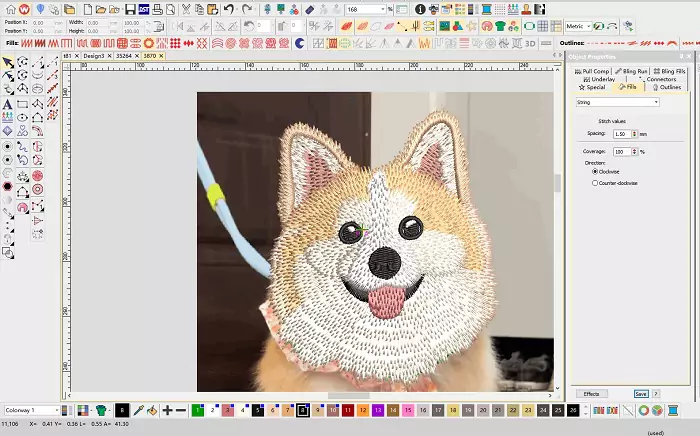

Many may be curious, or perhaps with a learning mindset, search for the question: After the designer has designed the embroidery pattern on wilcom digitizing software, what should they do next? Allow me to guide you through the daily operations of an embroidery artisan!

Upon receiving the embroidery design, the artisan must execute precise file storage and handover procedures. To ensure the entire process unfolds in a systematic and orderly manner. While these tasks may appear straightforward, they necessitate close collaboration and communication among various departments and personnel, as well as meticulous attention to detail and professional precision.

https://www.youtube.com/watch?v=ruJQJ7M1BJk

File Naming and Storage

The embroiderer stores the finished design in a specific folder. They then name and sort the design. Usually, they classify storage based on the company or factory name. They must save the file in the EMB format. This format allows the design file to be read and modified again. The EMB files are stored on a special disk. This disk is generally one that the company uses. If no dedicated disk is available, a regular disk will suffice. However, the company’s design files should be stored separately.

File Format

When storing files, the common format is the DST format. This is an embroidery file format, also known as the tape file format. These files are stored on a USB drive, which can be recognized when plugged into the embroidery machine, and then embroidery can start directly.

Handover Process

The embroiderer brings the stored files to the trial machine or test machine. Then, they start the embroidery. If a professional manufacturer is involved, the file can be handed to the embroiderer or foreman. They will then handle the initial processing. If necessary, they may need to rework the design on the Wilcom digitizing software.

During the handover, it is essential to package all the elements such as the pattern, drawings, and original information into a single folder to ensure completeness and avoid omissions. This handover procedure ensures the entire process is error-free and helps maintain workflow continuity and efficiency.

Throughout the pattern-making work, one should always maintain a clear and orderly work method. From file storage to the handover phase, meticulous attention to detail is crucial to ensure the integrity and efficiency of the work.

Modification Communication and Finalization Process

After the preliminary embroidery sample is completed on the embroidery machine, the pattern maker may still need to inspect and modify it to ensure the final pattern design meets the client’s requirements.

Initially, the embroidery artisan identifies areas that need modification by inspecting the preliminary embroidery sample, including any oversights or areas not meeting the requirements. These issues are then relayed to the pattern maker, who makes targeted modifications to ensure the pattern-making results are ideal.

Once the changes are complete, the embroiderer repeats the embroidery process. They then conduct a second round of checks. Since most of the changes were made during the first round, the second check is usually simple. If no issues are found during this check, the design file is sent to the customer for confirmation.

Once the customer confirms the design, the information is recorded. If the customer has further feedback or identifies issues, the process is repeated. This continues until the customer is fully satisfied. Once the changes are finished, the final design and embroidered version are registered. This includes recording details like thread color and angle. If the customer has chosen the fabric, a piece is cut and attached to the record sheet. Once the records are complete, they are stored in a file bag.

This process covers the pattern-making process from start to finish, and the pattern maker needs to strictly adhere to this process to ensure each piece meets the highest standards.

If you want to learn more about embroidery machines, wilcom digitizing software-related knowledge and usage skills, you can follow and visit our website. You can also directly participate in the discussion in the comment section.